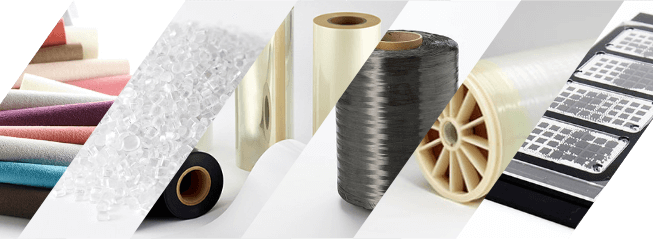

MATERIALS CHANGE OUR LIVES

News

Toray at a glance

Here is an overview of Toray, a material manufacturer that provides cutting-edge materials and continues to support innovation all around the world.

Sustainability

We make it our mission to deliver innovative technologies and advanced materials that provide real solutions to the challenges the world faces with balancing development and sustainability.

Four Perspectives of the World as Envisioned by the Toray Group in 2050

A net zero emissions world, where greenhouse gas emissions are completely offset by absorption

A world where resources are sustainably managed

A world with a restored natural environment, with clean water and air for everyone

A world where everyone enjoys good health and hygiene